*Corresponding Author:

Demissie Negash,

Meat and Dairy Industry Development Institute, Ethiopia

Tel: +25191208844

E-mail: demisenegash@gmail.com

Abstract

Many by-products have a substantial potential value as animal feedstuffs. The utilization of agro-industrial by-products may be economically worthwhile, since conventional feedstuffs are often expensive. However, livestock have historically utilized large amounts of well-known and widely-available traditional by-products such as oil meals, bran, middling’s, brewers’ grains, distillers’ grains, beet pulp and molasses. But less conventional by-products have become available, such as vegetable- and fruit-processing residues, whey and culinary wastes. Brewing industry generates a main residue, Brewer’s Spent Grain (BSG), which has good properties both for use in animal consumption and for thermal use, but contains a very high content of moisture (20-25%) dry matter content.

Currently, brewers often supply this material at low cost for use as livestock feed. Brewer’s grains, a by-product of beer production, are often used as a livestock feed. Because brewer’s grains provide protein, fiber, and energy, they can be useful in a variety of diets. Protein in brewer’s grains can meet a significant portion of supplemental protein requirements; in addition, they provide fiber and bulk in the diets of ruminants and horses. Brewer’s grains and other brewer’s by-products have also been fed to pigs, sheep, and poultry. Currently, the primary market for wet brewer’s grains is as dairy cattle feed. Brewer’s grains have historically been marketed wet or dry, but wet brewers grains currently make up the majority of the marketed product. The objective of this review is to document brewery by- products as alternative feed for high cost concentrate feeds for tackling feed shortage, preventing environmental pollution and improve productivity of animals.

Keywords

Brewers; Spent grain; Wet spent grains

Introduction

Nowadays, there is great political and social pressure to reduce the pollution arising from industrial activities. Almost all developed and underdeveloped countries are trying to adapt to this reality by modifying their processes so that their residues can be recycled. Consequently, most large companies no longer consider residues as waste, but as a raw material for other processes. Most by-product feedstuffs (BPF) result from the processing of commercial crops, the food processing industry and the fiber industry. By-product feedstuffs in the diets of ruminants support growth and lactation and result in the production of human edible food. Consequently, BPF are becoming increasingly more important in the food and fiber system because they are available for use as livestock feeds at competitive prices relative to other commodities [1].

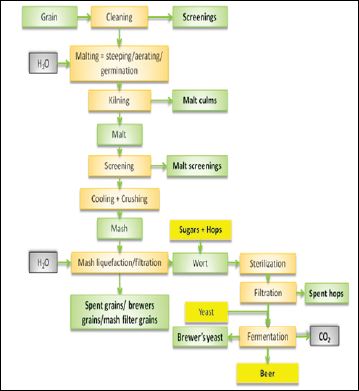

The brewing industry generates relatively large amounts of by- products and wastes; spent grain, spent hops and yeast being the most common. However, as most of these are agricultural products, they can be readily recycled and reused. Thus, compared to other industries, the brewing industry tends to be more environmentally friendly. In the brewing process the initial step involves the malting of barley [2,3].

There are several by-products that can be obtained from production of beer, such as, brewers grains (wet or dried), brewers dried yeast, etc. These by-products are considered to be good sources of un-degradable protein and water soluble vitamins (Janet 2009. They have been used in feeding both ruminant and monogastric animals (FN Madbuik 2007) [4,5]. Brewer’s grain is the material that is remaining after fermentation of grain, during the beer making process. This material can be used in the undried or dried form (WBG or DBG respectively). The nutritional content of the material will vary from one crop to another crop and depending upon the type of substrate (barley, wheat, corn, etc.), extent of fermentation and type of fermentative process. Brewers’ yeast has been successfully used as a replacer for soy in diets of growing and fattening pigs and sows [6].

Currently, use of brewery by-products to ruminants is relatively limited but the feed is very palatable and offers a good source of protein [7]. Common characteristic of the brewery by-products is that they contain increased or high crude protein concentrations: brewer’s grains 28-30 %, brewer’s yeast 50 %, brewer’s spent grain (calculated on dry matter basis). Attractive protein feed may be obtained by blending mentioned by-products [8].

Brewery by-products are used in several ways worldwide: direct inclusion of brewer’s spent grains and brewer’s yeast in animal diets. Drying of brewer’s spent grains and yeast and their inclusion as separate concentrates in animal diets, with liquid by-products being discharged as wastewater; blending of all by-products combining the brewery by-products as feed ingredients in a compound feed, thus allowing utilization of all brewery by-products in the form of an attractive feed of increased nutritional value. In recent times, a lot of research efforts have been focused on this last way of usage, which is gaining more and more supporters [8,9].

Brewing

According to [3,8] finding the brewing industry generates relatively large amounts of by-products and wastes; spent grain, spent hops and yeast being the most common. However, as most of these are agricultural products, they can be readily recycled and reused. Thus, compared to other industries, the brewing industry tends to be more environmentally friendly. Depending on the economic conditions, brewers’ yeast may be sold separately or dried and sold with the grains to yield a mixture of 95% dried brewers’ grains and 5% dried brewers’ yeast. Dried brewers’ grains may also contain 3% dried spent hops. Also the dreg, which amounts to 0.25-0.8% of the malt DM, is often mixed into the brewers’ grains. Consequently, this means that the brewers’ grains vary in their nutritive value.

Brewery Byproducts

Ellis R, Bird HR (2015) [10] revealed that, three byproducts of the brewing industry are important as animal feed-brewers’ dried grains, malt sprouts, and brewers’ dried yeast (Figure 1). Brewers’ grains are the residue of the barley after digestion and extraction of most of the starch. Malt sprouts are the roots from the sprouting of the barley during the malting process. Brewers’ yeast, which is separated from the mixture after fermentation, is valued primarily as a source of riboflavin, niacin, pantothenic acid, and choline. It is also relatively high in protein. Brewers’ grains are predominantly a cattle feed to be used interchangeably with other feeds of similar type as to bulk and crude-fiber and protein contents. Sometimes they are used as a partial replacement for grains in rations for cattle, sheep, and horses. Many researchers say that, dried malt sprouts are used chiefly in mixed feeds for dairy cattle, frequently along with brewers’ grains. Brewers’ yeast, being primarily a vitamin- rich supplement, is used in swine rations, in dog, fox, and mink foods, and in poultry feeds. The protein content is high and its contribution to diets is often significant. Brewers’ yeast also has been used successfully as a cattle feed. Dried fermentation soluble and dried distillers’ soluble are important sources of riboflavin and other water soluble vitamins for poultry. Dried brewers’ yeast is also used for this purpose and, although it does not furnish riboflavin at as low a cost as the soluble, it has some additional value as a source of choline. Distillers’ Grains with Soluble (DGS) contribute protein and vitamins to poultry diets, but their high content of fiber limits their use. Dried fermentation soluble and distillers’ soluble sometimes have a laxative effect if fed as 5 percent or more of the diet, especially if the diet contains other ingredients that tend to be laxative. Ordinarily the levels required to supply riboflavin are well below the laxative level.

Figure 1: The brewery by-products [11].

Spent brewers grain

According to [12], spent brewers grain is the most abundant brewing by-product, comprising 85% of by-products generated, 31% of original malt weight and 20 kilograms per 100 liters of beer produced. Since spent brewers grain is rich in sugars and proteins, the main and quickest alternative for elimination of this industrial by-product has been as animal feed. Spent brewers grain contains 75-80% water and deteriorates rapidly due to microbial activity. It is mandatory to use them as soon as possible after reception and to make sure that they are in good condition before utilization.

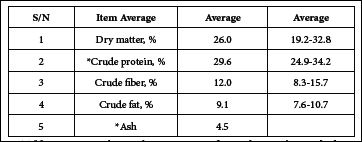

In order to correctly compare spent brewers’ grains to different feedstuffs, the comparison must be made on a dry matter basis. Most spent brewers’ grains are stored either in an on-farm bunker silo or a plastic bag. Regardless of the storage method, spent brewers’ grains will have a finite feed out period. Spoilage of spent brewers’ grains can occur in as little as five to seven days after the bag or silo is opened, and this leads to increased mold growth, decreased moisture content, and decreased palatability. This can be costly for farms if their feeding rates fall below the rate of spoilage [13]. Variability exists in the nutrient composition of spent brewers’ grains just like every other by- product feedstuff. The following table indicates the normal range for each chemical component (Table1).

Table 1: Average chemical composition of spent brewers’ grain [14].

For an accurate comparison of the costs and utilization of spent brewers’ grains, the cost of the spent grains should be adjusted to a similar moisture level as other dry feedstuffs. Many feedstuffs are approximately 90% dry matter, whereas spent brewers’ grains are 20 to 32% dry matter.

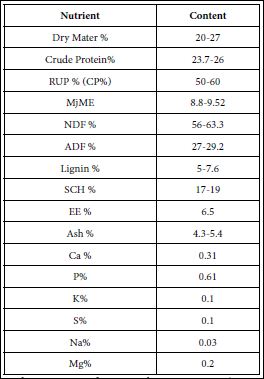

Since spent brewers’ grains are delivered in bulk, appropriate feed storage and handling systems need to be available. The physical form of spent brewers’ grains are a loose, fibrous grain residue, and this necessitates the use of a front-end loader or similar equipment for handling, feed wagons for transport, and adequate feed bunk space for delivery. Comparison of spent brewers’ grains with other feedstuffs should be made based on price per unit of energy, protein or labor on a similar moisture or dry matter (Table 2).

According to [15,16], the short lifespan of the wet spent brewery grain is the critical problem of farmers when utilizing this by-product. Ensiling of wet brewery grain either alone or along with other feed is ecologically and economically feasible, and easily applicable from a technological view point to dairy farmers in Ethiopia. The selection of right conservation method is crucial for storing and utilizing this feed without spoilage.

Spent yeast

Mathias et al., 2014 say that, during the fermentation process, yeast cells can multiply numerous times, which results in markedly greater yeast mass than what is added at the start of fermentation. The yeast growth rate is influenced by the fermentation conditions at each brewery. The typical volume of spent yeast collected from a lager fermentation is approximately 2 kg/hl of the final volume of beer produced. Similar to spent grain, some breweries sell their spent yeast as animal feed.

Table 2: Nutritional composition of wet spent brewery grain in (expressed on DM %).

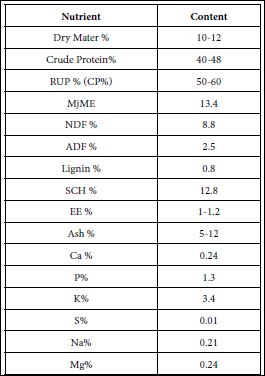

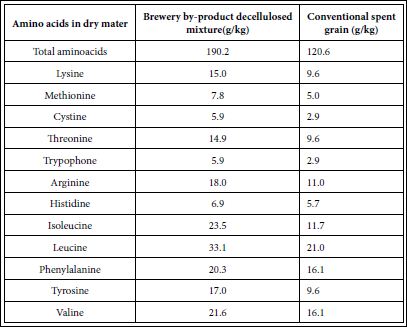

The [17] finding state that, the potential of spent yeast as a source of protein, minerals and B-complex vitamins, and high quantities of essential amino acids might provide additional opportunities to the farmers if used correctly. The water content of this product is very high (88-90%), and the main nutrients (Table 3) are in suspension, which difficult its direct use on farm, unless a special strategy aimed to address this matter is used. This should involve the homogenization of the product before being used (agitator, mixer, and homogenizer) (Table 4).

Table 3: Nutritional composition of wet spent brewery yeast [11].

Table 4: Amino acid composition of brewery by-product decellulosed mixture pro- duced from combined brewery by-products [18].

Wet brewers’ Grains

Westendorf and Wohlt 2002 [8] study state that, Wet Brewers’ Grains (WBG) are the by-product of the beer-brewing industry. The WBG are the spent grains, most often barely, but some corn and/ or rice may be included depending on the source of the grains. In a review summarized the nutrient content of WBG and determined that the protein, fiber, and energy concentration of WBG make them a suitable supplement in both ruminant and nonruminant diets. However, because of the protein concentration and high fiber concentration, WBG may be more beneficial in a ruminant diet to support rumen function and animal production.

Feed characteristics: Different authors agreed with, wet brewers’ grains have low dry matter content, reasonable protein source and high content of Total Digestible Nutrients (TDN) due to the digestibility of the available fiber [19]. This high concentration of fiber of WBG is because the starches and sugars are removed from the barley grain during the malting process leaving mainly the structural cell wall carbohydrates of cellulose and hemicelluloses [8]. The energy value of WBG is approximately 71 to 75% TDN, compared to corn, which has a TDN value of 88%. This energy is mainly derived from the highly digestible fiber in WBG. The digestible fiber of WBG is an excellent complement to forage-based diets that lack starch and readily fermentable fiber. Additionally, WBG contain 7 to 10% crude fat, which contributes to the total energy value of WBG [20-22].

Wet brewers’ grains are a good source of protein with a crude protein content that ranges from 25 to 34% (Table 4). The protein is mainly located in the germ portion of the spent grain and is digested to a limited extent in the rumen and to a greater extent in the small intestine. The concentration of rumen degradable protein ranges from 28 to 43% with a mean of 35%, indicating that WBG are good sources of rumen undegradable or “bypass protein”. Wet brewers’ grains are low in calcium and potassium, similar to other cereal grains. The calcium: phosphorus ratio is inverted compared to the National Research Council recommendation of 7:1 to 1:1. Therefore, more phosphorus is supplied relative to calcium from WBG. A well- balanced mineral supplement should be supplied when using WBG in cattle diets to avoid the negative effects of decreased growth performance experienced when this ratio is not properly balanced.

References

- Hersom MJ (2006) By-product feed utilization for forage diets. In: 55th Annual Florida Beef Cattle Short Course, Gainesville: University of Florida Institute of Food and Agricultural Sciences 5-14.

- Mussatto SI, Dragone G, Roberto IC (2006) Brewers’ spent grain: Generation, characteristics and potential Journal of Cereal Science 43: 1-14.

- Ishiwaki N, Murayama H, Awayama H, Kanauchi O, Sato T (2000) De- velopment of high value uses of spent grain by fractionation MBAA Technical Quarterly 37: 261-265.

- Taylor J, Taylor JRN (2009) Some Potential Applications for Brewers Spent Grains the rotein-rich co-products, from sorghum lager beer brewing, 12th scientific and technical convention.

- Madubuike F, Ekenyem B, Obidimma V (2007) Optimum Substitution Level of Maize with Spent grain in Broiler Finisher Journal of Agriculture and Food Sciences 5: 21-28.

- Wlcek S, Zollitsch W (2004) Sustainable pig nutrition in organic farming: By-products from food processing as a feed Renewable Agriculture and Food Systems 19:159-167.

- Dhiman TR, Bingham HR, Radloff HD (2003) Production response of lactating cows fed dried versus wet brewers’ grain in diets with similar dry matter content. Journal of Dairy Science 86: 2914-2921.

- Westendorf LM, Wohlt EJ (2002) Brewing by-products: Their use as animal Veterinary clinics of North America Food Animal Practice 18: 233-252.

- MussattoSI, Dragone G, Roberto IC (2006) Brewersõ spent grain: Generation, characteristics and potential applications. J Cereal Sci 43: 1-14.

- Ellis R, Bird HR, (2015) By-products as Feed for Livestock.

- https://www.feedipedia.org/node

- Mohammed D, D Addis D, Berhanu T, Vernooij A (2019) Mapping of spent brewers’ grain supply chain in Ethiopia. Wageningen Livestock Research Report 1210 5-23.

- Radzik-Rant A, Rant W, Nznikowski R, Swiatek M, Szymanska Z, et al. (2018) The effect of the addition of wet brewers grain to the diet of lambs on body weight gain, slaughter value and meat Arch Anim Breed 61: 245-251.

- Buffington J (2014) The Economic Potential of Spent Brewers Grain as a Biomass Feedstock. Advances in Chemical Engineering and Science 4: 308-318.

- Feyissa F, Assefa G, Kebede G (2015) Mineral profiles of agro-industrial by-products and locally available supplementary feeds and their implications for dairy cattle nutrition in Ethiopia. Eth J Anim Prod 15: 17-30.

- Demeke S (2007) Comparative nutritive value of Atella and industrial brewers grains in chicken starter ration in Livestock Research for Rural Development 19.

- Aranguiz AA, Berhanu T, Vernooij A (2019) Utilization and management of spent brewers grain in Ethiopian dairy farms. Wageningen Livestock Research report 1207: 5-27.

- Levic J, Djuragic O, Sredanovic S (2010) Use of new feed from brewery by-products for breeding Romanian Biotechnological Letters 15: 5559-5565.

- Grasser LA, Fadel JG, Garnet I, Depeters EJ (1995) Quantity and eco- nomic importance of nine selected by-products used in California dairy J Dairy Sci 78: 962-971.

- Kaur VI, Saxena PK (2004) Incorporation of brewery waste in supple- mentary feed and its impact on growth in some Bioresource Tech- nology 91:101-104.

- Rocha MST, Mello PPM, Sérvulo EFC (2014) Solid wastes in brewing process: A Journal of Brewing and Distilling 5: 1-9.

- Aguilera-Soto JI, Ramirez RG, Arechiga CF, Lopez MA, Banuelos A, et al. (2007) Influence of wet brewer’s grain on rumen fermentation, di- gestion and performance in growing lambs. J Anim Vet Adv 6: 641-645.

Citation: Negash D (2021) Use of Brewery by-Products as Animal Feeds. J Nutr Food Sci 4: 027.

Copyright: © 2021 Negash D. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and re- production in any medium, provided the original author and source are credited.