*Corresponding Author:

El Zubeir IEM,

Department of Dairy Production, Faculty of Animal Production, University of Khartoum, Sudan

Tel: +249 185321246

E-mail: elisabeth.baeza-campone@inrae.fr

Abstract

Purpose: This study was conducted to evaluate the chemical composition and acceptability of ice cream flavored with African fan palm (Borassus aethiopum) and muskmelon (Cucumis melo L.) fruits Juices.

Methods: Before the processing of ice cream, cow’s milk was examined for compositional content. The milk was first subjected for heat treatment (72 °C for 10 seconds). Then the ice cream mix was made by adding juice, sugar, skim milk powder and Gum Arabic. After gentle homogenization, the mixture was cooled to about 5 °C and then divided into 2 portions; either African fan palm or muskmelon was added as a flavor. Each flavored ice cream mix was made separately using the ice cream machine. The ice cream samples were packed into plastic cups and stored for 60 days in a deep freezer (-18 °C for 10 seconds). The analysis for chemical composition and the sensory attributes were conducted bimonthly.

Results: The result revealed non-significant differences in protein, fat and ash content between the two types of ice cream. However the total solids content of the ice cream samples flavored with fruits juice of African fan palm revealed significantly (P≤0.01) high values compared to ice cream samples flavored with muskmelon fruits juice. Also significantly (P≤0.05) higher scores of color, taste, texture and overall acceptability were obtained for ice cream flavored with fruits juice of African fan palm.

Conclusion: The present study encourages and recommends processing and consumption of ice cream flavored with natural fruits like African fan palm and muskmelon that available locally because of their nice flavors.

Keywords

African fan palm ; Chemical composition; Ice cream; Juice; Muskmelon; Processing; Sensory evaluation

Introduction

Ice cream is frozen dairy food made by freezing a pasteurized mix with agitation to incorporate air and to ensure uniformity of consistency [1]. Ice cream is a popular dairy product throughout the world. As a result, its production and consumption are rapidly increasing and the substantial part of milk produced in many countries is being utilized for the manufacture of frozen dessert [2]. The major constituents (ingredients) in the ice cream formula backbone are milk fat, milk solids not fat, sweetener, stabilizer and/or emulsifiers, water and air [3]. The ingredients and processing steps required to produce good ice cream are well known and are employed worldwide [4,5]. Consequently, ice-cream plays an important role of actual food which, besides its digestive and metabolic qualities, has nutritive qualities, but can also influence the mind because of its organoleptic characteristics and its importance as thermoregulatory food in the fight against heat [6].

There are certain foods that cannot be eliminated from human diets such as fruits [7]. Fruits are good sources for the fortification of ice creams because of their sweet and desired taste and aroma. They provide flavor and texture contrast as well as an attractive product appearance. Muskmelon is normally eaten as a fresh fruit, as salad or as a dessert with ice cream or custard [8]. Consumer preference for Muskmelon (Cucumis melo L.) fruit is determined largely by its sweetness, flavor or aroma, texture and more recently as a rich source of phytonutrients [9]. Cucumis melo, in addition to its superior consumer preference, is an extremely healthful food choice as they are rich in ascorbic acid, carotene, folic acid, and potassium as well as a number of other human health-bioactive compounds [10]. The fruit have a high soluble solids content ranging from 10 to 16 Brix [11].

In many rural areas in tropical developing countries, African fan palm tree is a source of numerous substantially important products, providing food, household medicines, fuel, and wood for building and household tools but also primary materials for local industries [12,13]. A trial to produce ice cream from camel milk, recommended that further studies should be conducted on making ice cream by adding natural fruits to enrich nutritional and health benefit and to give nice flavors [14]. Moreover because tropical fruits; being rich in functional bioactive; are valued as one of the potential sources of antioxidants, in addition to its enhancing the shelf-life and quality of the products as well as protecting the biological systems [15]. Hence this study aimed to process ice cream from camel milk flavored with African fan palm and muskmelon as local natural fruits available in Sudan. Some of the chemical composition and sensory properties of the produced ice creams were compared and evaluated.

Materials and Methods

Preparation of ice cream mix

The experimental procedures were done in specialized small processing unit that located at Khartoum North during the period from June 2014 to August 2014. Fresh raw whole cow milk (7 liters) was obtained from Khartoum University farm. African fan palm was obtained from Abo-Karshola, while Gum Arabic, Muskmelon, sugar, skim milk powder and low fat cream were obtained from local market of Khartoum.

Before the processing of ice cream, there were some pilot trials of manufacturing ice cream by several percentages of Gum Arabic, concentrate of one of two natural flavors (African fan palm and Muskmelon) and skim milk powder. The successful production of ice creams was done using 0.3 Gum Arabic and 12% sugar for one litter of mix ice cream in addition to 12% skim milk powder. Then the ice creams were made by two natural flavors; either14% of African fan palm juice or 10% Muskmelon juice. The chemical and sensory evaluations were done during the storage of ice cream.

Preparation of juices

African fan palm

African fan palm fruit juice was prepared by cleaning and removing the outer shell then the pulp was taken from the fruit and soaked for 12 hours in 1.14 litter of water then the juice was collected, filtered and added to a mixture of ice cream.

Muskmelon

To prepared muskmelon, it was first cleaned thoroughly with water and the outer shell was removed and the pulp was cut into slices and mixed before adding to the mixture of ice cream.

Manufacturing of ice cream

Manufacturing of ice cream was described previously [14]. Milk (7 litter of cow milk) was pasteurized by HTST, Then juice of African fan palm or Muskmelon, sugar, Gum Arabic and skim milk power were added. After cooling the mix in the refrigerator for 5 °C, it was divided into 2 portions and flavors juices were added. Each mix was derived into ice cream machine and the ice creams with the 2 flavors (African fan palm and Muskmelon) were made. The packaging was done into plastic cups (125 gm) and then the ice cream was stored at -18 °C in a freezer for 60 days.

Examination of milk and ice cream

The examination of milk and ice cream were carried out in duplicate at the laboratory of Department of Dairy Production, Faculty of Animal Production, University of Khartoum.

Milk analysis

The milk samples were analyzed by Lactoscan (Milkotronic LTD, Europe) according to the instruction provided in the accompanied technical manual.

Chemical analysis of ice cream

The total solids content of ice cream samples were determinate according to modified method [16]. The fat content was determined by Gerber method [17]. The protein content was determined by Kjeldahl method and the ash content was determined by gravimetric method [16].

Sensory evaluation

Ten untrained panelist were chosen to judge on the quality of ice cream in terms of color, flavor, texture, taste, and the overall acceptability, using a sensory evaluation sheet. The judge was based on the ranking method (1–5 points headonic scale), where 5: excellent, 4: very good, 3: good, 2: acceptable and 1: poor [18].

Statistical analysis

The data were analyzed using SPSS 14. The significant differences between means were determined and separated by using Duncan’ Multiple Range Test (P≤0.05).

Results

Chemical composition of milk

Chemical composition of cow milk sample was analyzed by Lactoscan. The means were found as 9.3%, 3.67%, 4.9% and 4.2% for solids non- fat, protein, lactose and fat content, respectively.

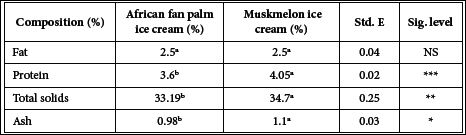

Chemical composition of African fan palm and Muskmelon ice cream

Total solids of ice cream

The total solids reveled significant (P<0.05) differences between African fan palm and Muskmelon ice cream samples (Table 1). The highest average of total solids content was found in Muskmelon ice cream samples (37.2%, 34.7%, 34.65%, 34.23%, 32.9%) compared to African fan palm ice cream samples. (35.5%, 33.65%, 32.89%, 32.25%, 31.69%) as shown in Figure 1.

Figure 1: Variation of total solids content of ice cream flavored with African fan palm and Muskmelon during storage.

Fat content of ice cream

The fat content revealed non significantly (P>0.05) differences (Table 1). Result in Figure 2 showed the fat content of natural flavored ice cream during the storage period. The highest mean value of fat was reported for African fan palm ice cream (2.9%) during day 60, while the lowest mean value was found in Muskmelon ice cream samples (2.05%) during day 45 as shown in Figure 2.

Figure 2: Variation of fat content of ice cream flavored by African fan palm and Muskmelon during storage.

Protein content of ice cream

Result in Figure 3 showed that the protein content of different natural flavored ice cream during the storage period. The protein content revealed non-significant (P>0.05) differences between the different types of ice cream during the storage period expect for Muskmelon ice cream during day 45 and 60 of storage and African fan palm ice cream during the day 5 and day 15 of storage. The highest means value of protein was found in Muskmelon ice cream sample (5.68%) during day 5, while the lowest means were found in African fan palm sample (1.95%) during day 60 of storage.

Figure 3: Variation of protein content of ice cream flavored with African fan palm and Muskmelon during storage.

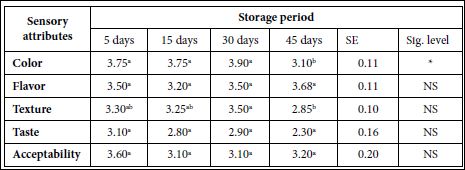

Ash content of ice cream

The ash content of natural flavored ice cream revealed significant (P<0.05) differences between African fan palm and Muskmelon ice cream samples (Table 1). Result in Figure 4 showed the ash of natural flavored ice cream during the storage period. The highest mean of ash were found in Muskmelon ice cream samples (1.8%) for day 15, while the lowest mean value was found in African fan palm ice cream samples (0.755±0.085%) as shown in Figure 4.

Table 1: Comparison of chemical composition of ice cream flavored by African fan palm and Muskmelon.

Means within each row bearing similar superscripts are not significantly different (P>0.05).

NS: Not significant ; * P < 0.05; ** P < 0.01; *** P < 0.001.

Figure 4: Variation of ash content of ice cream flavored with African fan palm and Muskmelon during storage.

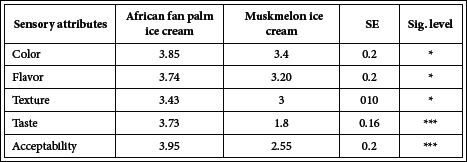

Sensory evaluation for ice cream flavored with African fan palm and Muskmelon during storage

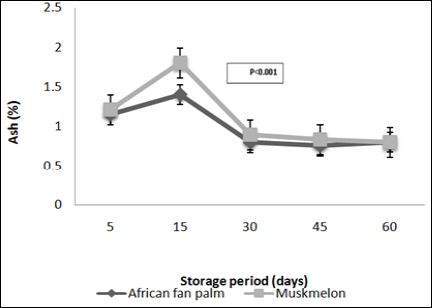

The sensory evaluation measurements (Table 2) revealed significant (P<0.05) differences for the type of ice cream samples. The higher scores of all sensory characteristics was found in African fan palm ice cream sample during storage period as shown in Table 3.

Table 2: Comparison of sensory evaluation of ice cream flavored by African fan palm and Muskmelon.

* Significant: (P<0.05); ** P<0.01; *** P<0.001.

Discussion

Evaluation of ice cream processing using African fan palm and Muskmelon juices were tried in the present study in order to assess its chemical (Table 1 and Figure 1-4) and sensory properties during 8 weeks of storage (Table 1 and Table 3). Different concentration of the selected juices and Gum Arabic were examined before investigation of the ice cream formula. In the present study, the Gum Arabic was added as stabilizer and emulsifier, because of its of availability in Sudan, in addition to its health benefit [19]. Moreover today, Gum Arabic has been widely used as a stabilizer, a thickener and/or an emulsifier e.g., soft drink syrup, gummy candies and creams [20]. Gum Arabic is added to produce the same opacity, appearance, mouth feel and palatability as natural fruit juices [21].

Table 3: Effect of storage period on sensory evaluation of ice cream flavored by African fan palm and Muskmelon.

Means within the each row bearing similar superscripts are not significantly different (P> 0.05).

NS: Not significant: (P > 0.05); * Significant: (P < 0.05)

The higher average of total solids was obtained in Muskmelon ice cream samples and the lowest means for total solids content was found in African fan palm ice cream samples (Table 1 and Figure 1). The present result was in consistent with the finding reported that the mean of total solids was 33.40±2.87% [22]. This could be due to the high soluble solids content of Muskmelon fruit that recorded a ranging from 10 to 16 Brix [11]. The ice cream containing larger ice crystals showed lower total solids value [23]. Hence adequate total solids content is important for obtaining a good product with a smooth texture and firm body [24].

The fat content in this study was not significantly (P0.05) different. The highest mean value of fat was reported for Muskmelon ice cream (2.7%) during day 15, while the lowest mean value was found in African fan palm ice cream sample (1.9%) during day 30 (Table 1 and Figure 2). This supported Murtaza [25] who stated that there were non significant effects on fat content during storage of ice cream. No change in fat upon storage was also reported previously [26]. Both types of the fruits used as well as camel milk were proved to be good antioxidant, which is mainly because of their high vitamin C content. This will be of significant when incorporated in camel milk ice cream to fight against cancer and other diseases, which supported the camel milk as functional food [14,27].

The highest mean value of protein was found in Muskmelon ice cream samples (5.68%) during day 5, while the lowest means were obtained for African fan palm samples (3.6±0.06) during day 45 (Table 1 and Figure 3). This could be due to the reason that Muskmelon is a rich source of vitamin C, ß-carotene, vitamin A, carbohydrates, sugars, protein and also traces of vitamin B6, vitamin K, niacin, vitamin B2 and vitamin B1. In addition, this fruit contains more than 90% water [28]. The present result was consistent with the finding of Khater and El Owni [22] who reported 2.69±1.03% protein in ice cream. Similar results also stated that there were non significant effects on protein content during storage of ice cream [25].

This study showed the highest mean of ash was in Muskmelon ice cream samples (1.8%) during day 15 compared to those reported for African fan palm ice cream samples (0.75%) as shown in Table 1 and Figure 4. Similarly Khater and El Owni [22] reported that the ash of ice cream was 0.64±0.19. The higher ash content in Muskmelon ice cream might be because Muskmelon is rich in potassium [10].

The higher scores of all sensory characteristics were reported for African fan palm ice cream samples (Table 2 and Table 3). However it was reported that consumer preference for Muskmelon is determined largely by its sweetness; due to its sugar content; flavor or aroma, texture and more recently as a rich source of phytonutrients [9]. The present finding encourages the use of African fan palm in ice cream making especially those made from camel milk.

Various factors were found to contribute to the differences of sensory evaluation scores. It was found that the flavor of ice cream samples differed significantly due to variation in milk fat [29]. During the storage, both types of ice cream showed variations (Table 2 and Table 3). Deterioration in sensory quality of ice cream with the passage of time was reported previously [30]. Also the body, texture, flavor and taste were affected significantly due to the difference in stabilizer/ emulsifier combination and storage period [31]. The texture of the ice cream depends on many factors such as the state of aggregation of the fat globules, the amount of air, the size of the air cells, the viscosity of the aqueous phase, and the size and state of aggregation of ice crystals [4,32]. Ice-cream in addition to its nutritive qualities can also influence the mind because of its organoleptic characteristics and its importance as thermoregulatory food in the fight against heat [6]. However, it was noted that with the passage of time, scores for flavor, taste, and body/texture declined (Table 3). Also a gradual decrease in the scores for all the sensory characteristics of the ice cream samples during storage was found.

It is concluded that ice cream can be processed by adding Muskmelon and African fan palm juices. Gum Arabic as ice cream stabilizer could be used in ice cream flavored with African fan palm and Muskmelon. The development of new varieties of ice cream is based on either the milk, cream and whey concentrates and flavored with fruit and vegetable extract [33]. The highest score for flavor and color were recorded in ice cream samples flavored by African fan palm. The present study encourages the processing and consumption of ice cream made by additives of natural flavors and fruits; of approves antioxidant properties; available in Sudan. However further studies should be designed by adding local fruits and other additives to increase the nutritional and health benefits and to give good flavor ice cream.

References

- Arbuckle WS (1986). Ice Cream, 4th ed. Avi Publishing Co. Inc., West Port Connecticut. USA.

- Elahi ATM, Habib MM, Rahman GI, Bhuiyan MJ (2002) Sanitary quality of commercially produced ice cream sold in the stores. Pak J Nut 1: 93–94.

- Varnam AH, Sutherland JP (1994) Milk and Milk Products: Technology, Chemistry and Chapman and Hall, London, U.K.

- Granger C, Leger A, Barey P, Langendorff V, Cansell M (2005) Influence of formulation on the structural networks in ice International Dairy Journal 15: 255–262.

- Segall KI, Goff HD (2002) A modified processing routine for Ice cream that promotes fat destabilization in the absence of added Emulsifier. Int Dairy J 12: 1013–1018.

- Del Giovine L, Piccioli A (2003) Determination of synthetic dyes in Ice cream by capillary electrophoresis. Food Control 14: 131–135.

- Pamplona-roger GD (2008) Healthy Foods. 1st. Edition, San Fernando de Henares, Madrid, Spain: European Union.

- Parle M, Singh K (2011) Muskmelon is eat- International Research Journal of Pharmacy 2: 52–57.

- Lester GE (2008) Antioxidant, sugar, mineral, and phytonutrient concentrations across edible fruit tissues of orange- fleshed Honeydew melon (Cucumis melo L.). Journal of Agricultural and Food Chemistry 56: 3694–3698.

- Lester GE, Hodges DM (2008) Antioxidants associated with fruit senescence and human health: Novel orange fleshed non-netted honey dew melon genotype comparisons following different seasonal productions and cold storage durations. Postharvest Biology and Technology 48: 347–354.

- Guérineau C, Denis E, Scandella D, Navez B, Lancelin N (2000) Sensory evaluation of Charentais-type melons: An exploratory Acta Hort 510: 487–492.

- Rugalema GH, Okting-Ati A, Johnsen FH (1994) The home garden agro forestry system of Bukoba district, North-Western Tanzania. Farming system analysis. Agrofor Syst 26: 53–64.

- Sullivan S, Konstant TL, Cunningham AB (1995) The impact of utilization of palm products on the population structure of the vegetable Ivory-palm (Hyphaene petersiana, Arecaceae) in North-Central Namibia. Econ Bot 49: 357–370.

- Ahmed ASM, El Zubeir IEM (2015) Processing properties and chemical composition of low fat ice cream made from camel milk using natural additives. International Journal of Dairy Science 10: 297–305.

- Duthie SJ, Ross MA, Collins AR (1996) Antioxidant supplementa- tion decreases oxidative DNA damage in human Can- cer Research 56: 1291–1295.

- AOAC (2003) Association of Official Analytical chemist. Official Methods of Analysis, 16th ed. Washington, D.C.

- Bradley RL, Arnold JE, Barbano JDM, Semerad RG, Smith DE et al. (1992) Chemical and Physical Methods. In: Standard Meth- ods for the Examination of Dairy Products, 16th Marshall R.T., American Public Health Association. Washington, D.C.

- Ihekoronye LJ, Ngoddy PO (1985) Integrated Food Science and Technology for the Tropics. Edu., MacMillan Publishers, London.

- Elkhidir EE, Zubaidi BS, Yew TS (2010) Estimation of technical efficiency for share contract of producing Gum Arabic in Kordofan Gum Arabic Belt, Research Journal of Forestry 4: 185–193.

- Verbeken D, Dierckx S, Dewettinck K (2003) Exudates gums: Occurrence, production and applications. Applied Microbiology and Biotechnology 63: 10–21.

- Wyasu G, Okereke NZ (2012) Improving the film forming ability of Gum Arabic. J Nat Prod Plant Resource 2: 314–318.

- Khater ZK, El Owni OAO (2009) Chemical composition of ice cream produced in Khartoum state, Pakistan Journal of Nutrition 8: 158–160.

- Donhowe R, Hartel W, Bradley L (1991) Determination of ice crystal size distribution in frozen desserts. J Dairy Sci 74: 3334–3344.

- Marshall RT, Arbuckle WS (1996) Ice 5th ed., Chapman and Hall, Int. Thompson Publ. New York, USA.

- Murtaza MA, Din MU, Huma GN, Shabbir MA, Mahmood S (2004) Quality evaluation of ice cream prepared with different Stabilizers/ Emulsifier blends. International Journal of Agriculture and Biology 6: 65–67.

- Gwiszczynska A, Kaluziak H (1971) Changes in ice cream during storage. Food Sci Techno Abstr 3:142.

- Dowelmadina IMM, El Zubeir IEM, Arabi OHMH, Abakar AD (2019) Omega-3 fatty acids in milk fat of some Sudanese camels. J Dairy Research and Technology 2: DOI: 10.24966/DRT-9315/100009

- Anon (2002) Cantaloupe melon nutritional USDA Nutriment Database.

- Abd El-Rahman, AM, Shalabi SI, Hollender R, Kilarara A (1997) Effect of milk fat fractions on the sensory evaluation of frozen des J Dairy Sci 80: 1936–1940.

- Palich P (1994) Study of changes in the quality of ice cream during storage. Chlodnictwo 29: 21–25.

- Butt MS, Ahmad I, Mohmood, S, Shahzadi N (1999) Effect of different combination of stabilizer emulsifiers on the quality of ice Pak J Agri Sci 36: 70-73.

- Aime D, Arntfield SD, Malcolmson LJ, Ryland D (2001) Textural analysis of fat reduced vanilla ice cream products. Food Research International 34: 237–246.

- Olenev YUA (1989) The use of vegetable materials in ice cream manufacture. Dairy Science Abstract 5: 39–40.

Citation: Mohammed TMNE, El Zubeir IEM (2019) Evaluation of Chemical Composition and Sensory Properties of Ice cream Flavored with African Fan Palm (Borassus aethiopum) and Muskmelon (Cucumis melo L.) Fruits Juices. J Nutr Food Sci 2: 010.

Copyright: © 2019 Mohammed TMNE, El Zubeir IEM. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and re- production in any medium, provided the original author and source are credited.